Blog

What the heck is a Torpedo bat?

The NY Yankees have made headlines to start the 2025 MLB season with some historic run production after 5 players debuted the Torpedo bat (or Bowling Pin). The Bronx bombers smashed a record 15 home runs in 3 games. Baseball & media have been buzzing about the new bat design since. So what is it and why is it special? It’s a cool modern case study in product design.

The torpedo or bowling pin bat is a new design that is the result of a collaboration between a physicist turned baseball coach, baseball players, and bat manufacturers. It aims to optimize the existing bat material with a new form that maintains weight while increasing contact rates, contact quality and bat speeds.

What’s the objective here?

Baseball bats have not seen a lot of innovation, which makes sense for a product that has had 125 years to mature. The most recent step wise jump was a switch from ash to maple, which is denser, in the 1990s. When Aaron Leanhardt entered baseball from physics academia he brought a new perspective that allowed for some assumptions to be challenged and a new solution emerged.

In modern baseball, technology tracks a host of new metrics. Like golf, hitters care about bat speed. Higher bat speeds are correlated with harder hit balls that travel farther. Faster bat speeds allow for hitters to catch up to faster pitches or to see the ball for longer before swinging.

Another stat, exit velocity, measures the actual speed at which a ball leaves the bat. There is often some energy losses at contact based on the stiffness of the bat, swing mechanics, etc. The relationship between bat speed and exit velocity tells you about the efficiency of the energy transfer between objects.

Another important metric is launch angle. This is the angle relative to the ground at which the ball leaves the bat. This is affected by the shape of the bat’s barrel and the point of contact.

Bottom line – players want to swing as fast as possible so that they can catch up to more pitches and hit the ball so that it leaves the bat as fast as possible at the optimal angle range.

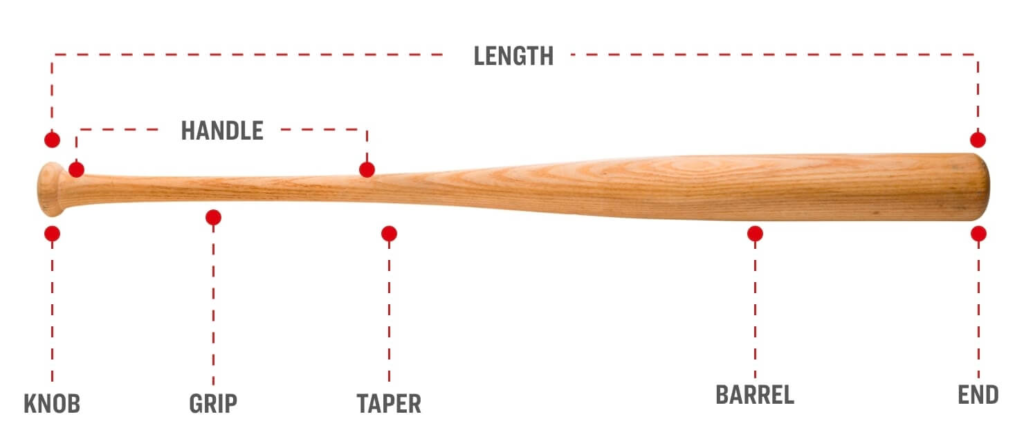

What does a typical bat look like?

The modern wooden bat cannot exceed 42″ in length, 2.61″ in max barrel diameter, and has to be made from a single piece of solid wood. The thickest part is usually 1-2″ from the end of the barrel and then tapers down in both directions.

What does a Torpedo bat look like?

The barrel of the torpedo bat is thickest closer to the sweet spot (ideal point of contact).

Ok, Why?

Leanhardt’s understanding of physics informed his instincts that there was a better way. He confirmed this in discussions with elite hitters.

Bat speed vs weight– Generally, lighter bats move faster. Two ways to increase bat speed are to remove material or to use less dense wood. However, if a bat is too light it will not generate enough exit velocity. Force is the product of mass and acceleration and momentum is the product of mass and velocity. There is a sweet spot range between speed and mass for each batter that is optimal.

Removing wood to decrease weight could result in a smaller barrel that makes it harder to make quality contact or make the bat less stiff or easier to break. Using a less dense wood will also yield larger losses between bat speed and exit velocity.

Small differences yield big results. Leanhardt approached the problem with a weight budget mindset – by fixing the weight and material of the bat and instead looking at new ways to distribute the material. His design moves material from the end of the bat toward the sweet spot.

First, this means the largest diameter of the barrel is at the point of contact. This improves a hitters chances of making good contact and affects launch angle. What was a miss on a smaller diameter could be a foul tip now. A foul tip could become a pop up. A pop up could become a home run. This results in improved contact rates for hitters.

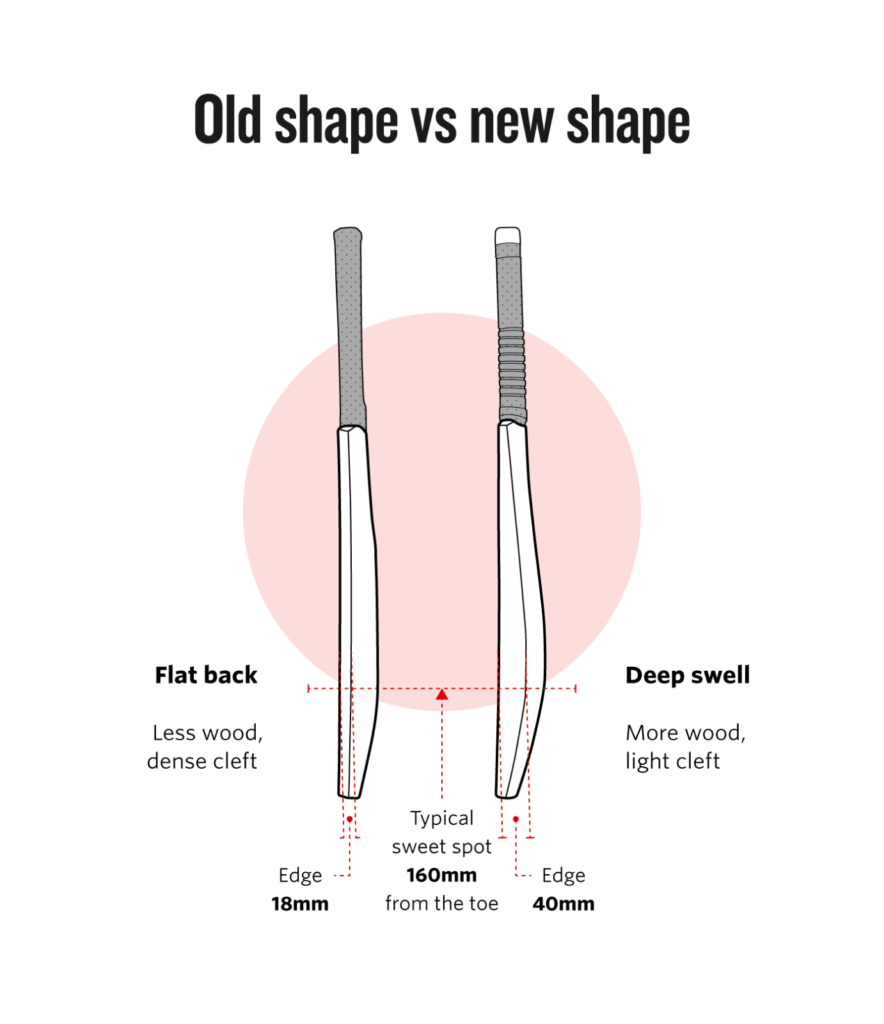

Cricket has been experimenting with these concepts as well.

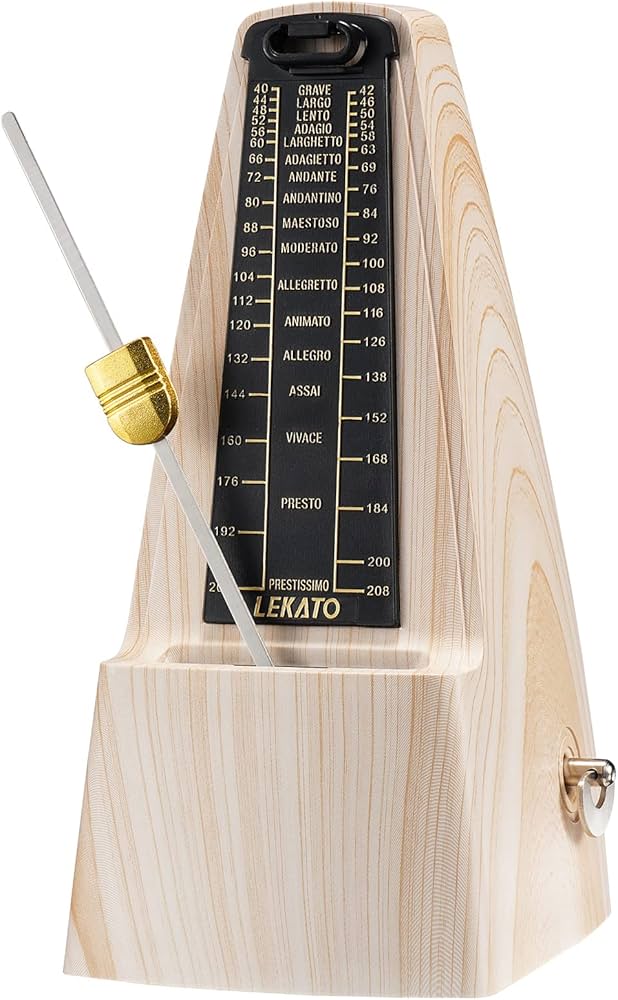

Second, moving the center of mass closer to the pivot point increases bat speed. We see this in action with a metronome. We can increase the beats per minute of the metronome by moving the weight down.

A batter can choose to trade off an increase in bat speed at the same weight or go to a heavier bat with the same bat speed but more force and momentum.

Is a sweet spot a real thing?

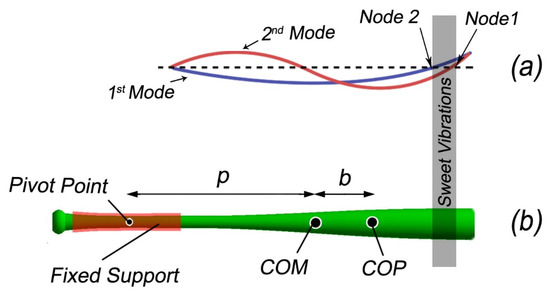

There is a location on every bat (about 6.5″ from the end of the barrel) that if the ball makes contact here then the shock of impact is almost undetectable to the hitter. There are actually two, but only one is practical for hitting.

When the ball makes contact at the sweet spot less energy is lost in the transfer to vibration of the bat. Bat designers agonize over fractions of an ounce of material here or there to precisely locate the sweet spot.

Conclusion

This new bat design is a great example of the value of new and diverse perspectives in challenging assumptions and finding fresh solutions. It’s also commendable that MLB leadership, players, and bat manufacturers are open minded to accepting innovation. Batting averages have been trending down and strikeouts have increased over time. Putting the ball into play more could improve the product experience for fans.